DIY

FRONT ROWING

RIG (click for VIDEO)

|

Much faster & longer range solo canoeing Much straighter than solo paddle or std. row Watch where you’re going & avoid collisions Row straight there or explore ahead Oars automatically feather on return stroke 16’ Canoe speeds can reach 8 mph burst |

- Legs-only rowing

allows taking video : waving; holding charts, binoculars; jig fishing etc.

- Arms pull against legs pushing for whole body exercise. Dead weight of

oars and legs supported

- Simpler and more compact than the FrontRower:

-1 pair of

major springs easy to make vs 2 pairs with difficult ends

-1 pair of pulleys vs 3 on the Front

Rower

-ball bearings for twist also roll to sweep the oar

-Simplified lighter aluminum frame with wood seat snaps in and out of

canoe

-Simple one piece foot

pedals. Light adjustable seat belt supports back

-Generally far fewer moving parts and lighter at 15 lbs total

-Simpler lighter handles allow most

comfortable pulling position

Prototype

Composite Oar

CLICK

for photo

of end view of pedestal

DESCRIPTION and MOTION

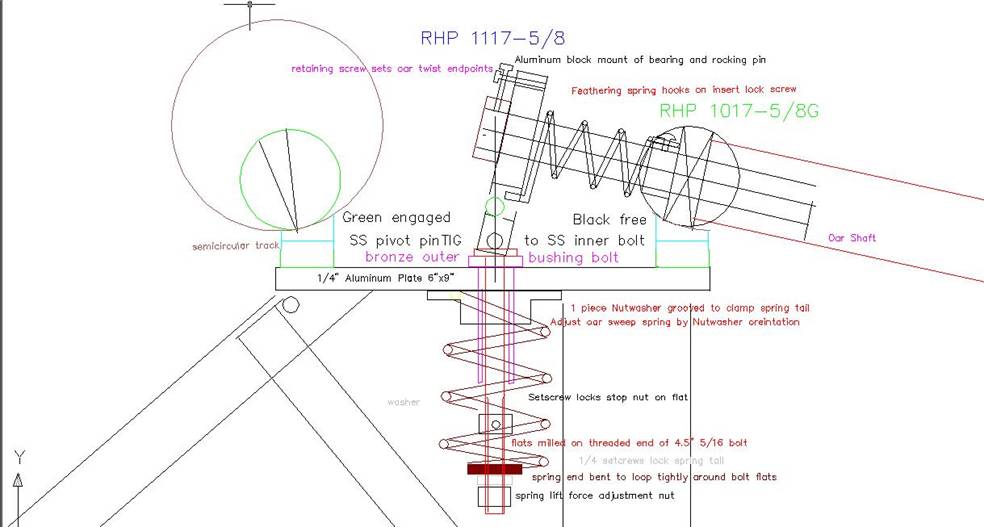

The oar

ends in a bearing in an alumimun block with a SS pivot pin through the bottom,

cutout in the middle where it is TIG welded in situ to the head of a long SS

bolt with its opposite threaded end milled to have side flats. The bolt and so

the bearing can rotate through a bronze machine screw sandwiching the pedestal

plate as well as slide up and down. A helical spring with one straight tail

clamped in the washer nut on the bronze machine screw, and the other tail formed to grip the flats of the bolt, spring loads the bolt and oar end down, and the oar forward. A setscrewed nut and washer set the vertical

travel and a nut below compresses the spring to set the lifting force.

About 3

inches outboard, a

pillow bearing insert rotates around the

oarshaft and its radiused

outside rolls on a steel track. It and the springloaded inner bearing support

the weight of the oar whilst allowing it to sweep depressed or lifted, and to

feather on its own axis. Feather stops on top of the inner bearing block limit

the extended setscrew of the inner bearing. Between the bearing block and the

outer bearing setscrew and around the oar is a light secondary spring (with

bent ends) which biases the oar towards feathered. The feathered limit is say 5° to

horizontal to ensure the lifted blade skips in any water contact and lifts in

the apparent wind. The tripped limit is the blade angled to vertical aft to

drive it down in the water, so the net blade turn is about 70°.

The ideal rocking point is at the same height as the track surface so

there is no in and out movement of the rolling wheel on the track just a change

in contact between its convex radius and the track’s greater concave radius. To

achieve this height match to the SS pivot pin and prevent wear a very short

6”XH steel pipe cutting is machined to the angle and radius and then split for

the two sides and tapped to receive machine screws through the pedestal plate. The foot

pedals hinges are tapped into the aft underside back of the pedestal plate

At 20.5”

outboard the rope wraps around the oar shaft, so the jerk from the seat pulley

unfeathers as well as lowers the oars to catch. This jerk is natural at the end

of the oar return as the slack comes out of the ropes. Once caught the blade

inclination to vertical drives the blade down into the water to a few inches

immersion as set by the limit on the mainspring compression. When the rope pull

from the arms and legs stops at the end of the sweep, the oar springs out of

the water to drain and then slowly feathers to clear the water on its return

and reduce the wind resistance. The oar’s emergence is aided by tilting the

pedestal forward about 5 deg relative to the waterline.

The oar

blades are curved shaftwise and angled so that they skip on any incidental

water contact on the return and lift in the headwind. Their edges should be

parallel to the water on entry and immersion to minimise the travel required.

For light rowing or at the finish of the stroke the top of the blades needn’t

be immersed and there is no loss by flow over the top, but for the beginning of

strong strokes the tops have to be immersed a few inches to prevent ventilation

destroying any suction behind the blades. The hatchet shape is close to ideal

and suggests composite shafts for the tapering, changes of section, and for a

very low tip weight to lift. In any case it is practically very important that

the blade ends do not leak any water into the oar shafts.

SPECIFICATIONS

Main springs: port left handed, starboard right handed approx

pitch of .142” music wire wound on ¾”

pipe mandrel 4 turns at about ½” pitch

finished OD about 1.7” Twist spring wire

Feathering springs: port left handed,

starboard right handed 6 turns .075” music wire OD about 1”

“rolling”

Bearings: RHP 1017-5/8G radiused Insert only for 5/8” pillow block $8x2

end insert bearing RHP 1117-5/8 $10x2

Oar Length 7.5’ Blades Average Depth 7.5” , Length

18 “,

DESIGN HISTORY of

ROWRIG for CANUDA PLY

A canoe hull

is suitable for open water fast rowing because unlike a shell it can have

static stability with a rowing rig and has sufficient freeboard for rowing against any

waves that may spring up. Its fineness and stability put it in between a shell

and a Whitehall dinghy. Since sliding seats are used in some Whitehalls and all

shells, they are appropriate for the intermediate canoe.

One drop-in

sliding seat rig attaches to a canoe’s gunnels but weighs 50 lbs, as much as

the canoe. The shorter waterline and recurved ends of the canoe vs. the shell

will exacerbate the oscillation of pitch

and surge as the rower slides, which

loses energy to radiative wave damping as well as increasing the average of the

quartic drag near the ‘hump’. The

rower’s feet push the boat back as he ends his recoil and begins a new forward

slide, slowing the boat even more at its slowest point. Likewise at the end of

the stroke his deceleration exacerbates the peaking of the hull speed against

the wave drag hump.

I conceived

of a sliding feet alternative where the seat and the rowers

cg is fixed and his feet and the oarlocks slide instead. A web search found http://www.rowvirusboats.com/virus/sliding_rigger.html

with this idea in a production shell. That site gives the history of the

sliding wing rig back to the 19th century, and its

banning by FISA when it indeed proved more efficient in racing in the

1980’s.The site animation shows the sliding feet driving the oarlocks back as

the arms swing the oars about them. Thus in a final advantage Virus do not

themselves recognise, the blade’s

velocity relative to the boat is increased, so the oars can be shortened. For

example with 8’ oars 6’ beyond the oarlock swung through 60 deg the stroke

relative to the boat of normally 6’

is increased to 7.5’ with a scull’s

18” slide.

A review

of the classic rowing motion shows that the main muscle duties are legs push

open by 1.5’ and lock, arms lock and flex by 1.5’, and finally the back hold

for these 3’ strokes and rotate for

another 2.5’. The strain on the back is out of all proportion to its

normal use in the body and explains why

back injury is the overwhelmingly predominant injury amongst rowers. Muscle

mass and comparative studies between leg and hand cranking on bicycles show the

legs are capable of about twice the

muscle power of the arms.

By raising the seat and

lowering the feet and having the stretcher pivot, the (foot) slide can be

easily raised to 24”. Then the hand grips of the oars needn’t move fore and aft

(see the return stroke of the Virus animation) and can be tied to the bow, as

well as elastically counterbalanced to the floor of the canoe. This saves arm

and back static muscle energy consumption on long distances; the arms only have

to twist and lower the oars during the leg stroke which reacts against the

weight on the seat as in cycling. (The Ro-Cat

http://www.rocat.co.uk/boat/rigger.htm exploits the lack of movement of the oar end in its slider

geometry but still has the hand and back muscles statically restraining the

end, consuming muscle power but doing no useful work.)

At the

end of the leg stroke, the arms and back can still be used to unload

the wire for extra sweep and especially

to steer. (The angle of such one-sided arm strokes doesn’t reduce its yaw

torque about amidships). Then the foot

movement is 2’ multiplied by 4:1 to give

8’ of blade movement whereas the arm

movement is 1.5’ max applied 3:1 for a blade movement of 4.5’, roughly ½ as required. In sprints, like on a

bike, arm pull also serves to brace the body against the extra leg force beyond what the seat can restrain.

But with

this evolution of the foot rowing concept to include cables restraining and

counterbalancing the oars at the inboard end, it is just a reversal of the

inboard end pivots and cables pulling

the ‘rowlock’ in http://www.frontrower.com . Ron Rantilla has so outraced sliding seats

with the same hull. His has the obvious advantages of seeing where one is

going, and only pivoting not linear

motions. The lack of overhanging riggers and the oars moving independently

movable very high makes docking much easier. Not least it alone can be rowed

hands-free or with

armpower throughout the stroke.

So it was decided to customise, lighten and if possible simplify this

system for the Canuda Ply.

The

frame was triangulated by a strut from the pedestal to the seat between the

legs, and by side stays from the pedestal to snap over the gunnels of the canoe

with a compression strut to the keel.The feathering

motion was made external and to use a

bearing in common with the sweeping motion. The oar lift and return springs

were combined by using easy to wind helical springs with straight ends clamped

in the pedestal and in bottom spring blocks, eliminating the return lines,

pulleys and springs. A simple seat belt from the pedestal looped around the

back provides comfortable adjustable back support.Another

pair of pulleys was eliminated from the leg drive, and a pair of moving parts

and pivots from the leg levers.